Mappers

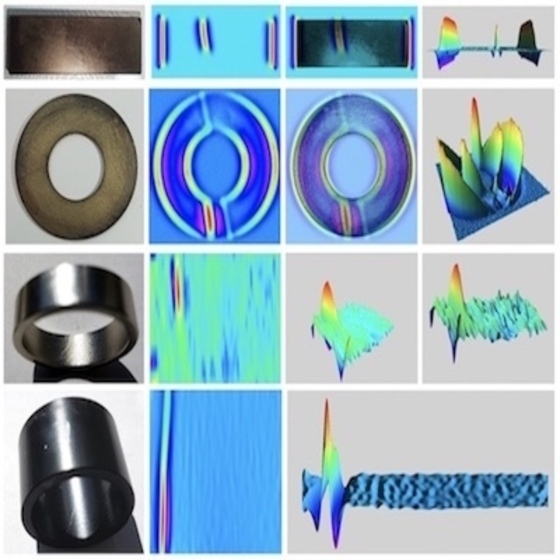

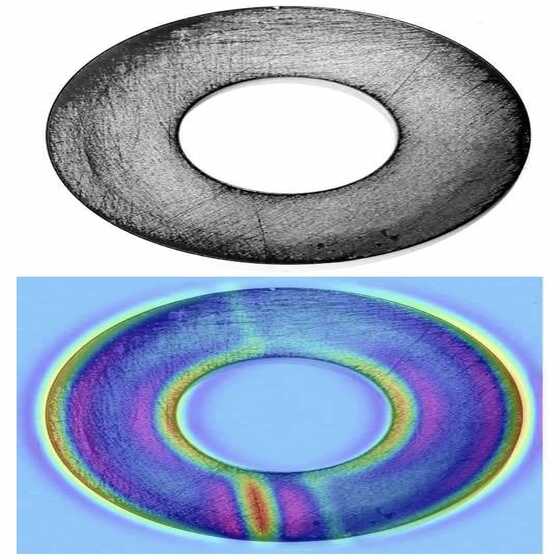

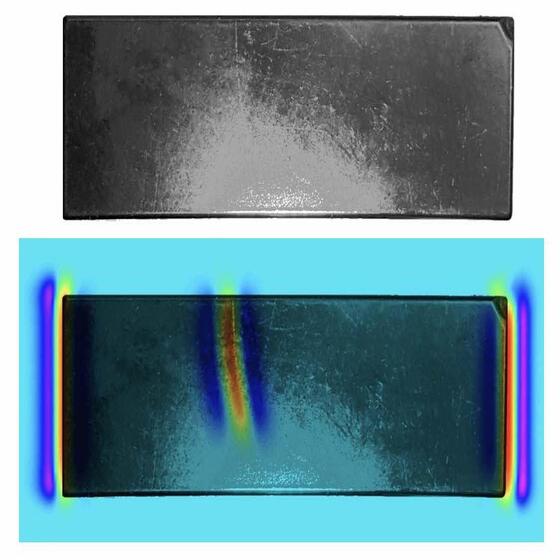

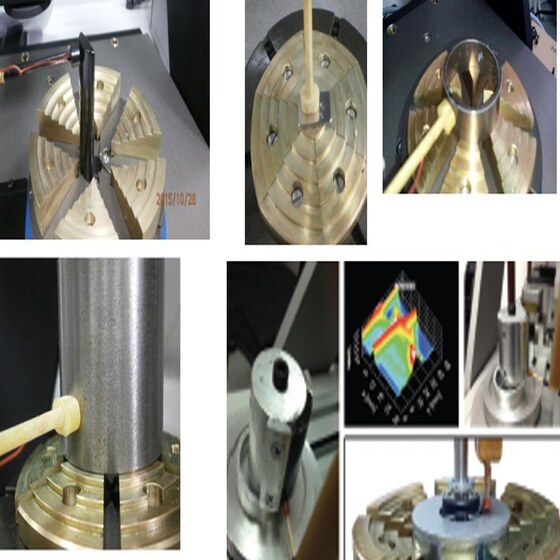

The SENIS Magnetic Flaw Detector Measurement System DEF-1C-IH2 can assist customers in quality control inspection tools used in production lines to detect cracks and inhomogeneities in magnets and non-magnetized components. Equipped with inductive sensors and magnetic Hall sensors, the Magnetic Defectoscope uses its innovative eddy current probe to detect uneven distribution of eddy current paths in fractured materials.

The 3-axis Hall probe is used to detect the magnetic flux density and the spatial polarity of the magnetic field, which can quickly check whether the iron parts in the production line are cracked and damaged. It has the software to automatically analyze and record the value of the extraction operation. By measuring the difference between the magnetic field induced value in the crack and the original material, the crack damage is engraved on the software, and the current distribution of the material can be quickly known.